Fiber Optic Splicing: The Heartbeat of Our Connected World

Ever wonder how that flawless video call with your colleague halfway across the globe happens without a glitch, or how you can download an entire season of your favorite show in minutes?

Probably not, but when everything works as it should, we tend to forget the complex network of connections that make it all possible. Behind that seamless connectivity, there’s a whole team of skilled professionals, many of whom are fiber optic splicers. Let’s take a closer look at what fiber optic splicing really is, and why it’s one of the most crucial pieces of the telecommunications puzzle.

What Is Fiber Optic Splicing?

Imagine holding a strand of glass as thin as a human hair. That’s a fiber optic cable. Inside that strand, pulses of light race through on multiple wavelengths, moving at nearly the speed of light and carrying up to 800 gigabits of data every second from one point to another. That’s enough bandwidth to stream more than 25,000 high definition videos at the same time through a single fiber. It’s not magic. It’s fiber optics in action.

Fiber optic cables aren’t always perfect lengths, though. They can get cut, bent, or even damaged during installation. And when that happens? Fiber splicing is required to keep the connection running smoothly. Think of it as a delicate surgery, stitching two pieces of fiber together to restore the flow of data.

There are two primary types of fiber splicing:

Fusion Splicing: This is the premium method for fiber optic splicing, where two fiber strands are joined by applying heat. It’s precise, efficient, and essentially permanent.

Mechanical Splicing: This is the faster fix. Using a small connector, the two fiber ends are held together. It’s quick, but not as durable as fusion splicing.

While both methods have their place, it’s the fusion splice that’s considered the gold standard. And let’s be clear, it’s not easy. It requires exceptional precision, skill, and the right tools. You can’t just grab a pair of scissors and go to town on fiber cables. Trust us, there’s a reason splicing isn’t a DIY project.

The Role of Telecommunications Contractors: Building the Infrastructure of Tomorrow

Have you ever seen a utility truck parked by the side of the road, with orange cones set up around it? That’s a telecommunications contractor in action, and they’re usually in the middle of splicing fiber cables to ensure a seamless connection.

These contractors aren’t just laying cables. They’re constructing the very infrastructure that powers the internet, television, and phone networks we rely on. They’re out there planning, installing, and troubleshooting, making sure everything runs smoothly.

But it’s not just city dwellers who benefit. National OnDemand is dedicated to bringing fast and reliable broadband to rural communities too. Because here’s the thing—reliable internet shouldn’t be a privilege for just urban areas.

A Day in the Life of a Fiber Splicer

Ever wonder what a fiber splicer’s day looks like? Spoiler alert: it may not look glamorous, but it’s critical.

Your alarm rings at 5:30 a.m. You grab a quick sip of coffee and start loading up your van with fiber reels, tools, and gloves that are well-worn from use. By 7 a.m., you’re on-site, and the real work begins.

You reach for the fusion splicer, a piece of equipment that can cost more than a pickup truck, and get to work. Every step demands precision: stripping away the protective coatings, carefully cleaning the glass, prepping the enclosure, and cleaving the fiber to a perfectly flat end. Even the smallest imperfection, just a fraction of a millimeter, can lead to a faulty splice and failed tests. And then you do it all again, whether under a blazing sun, in driving rain, or through freezing snow. Because the internet never stops and neither do the people who splice the fibers that keep it running.

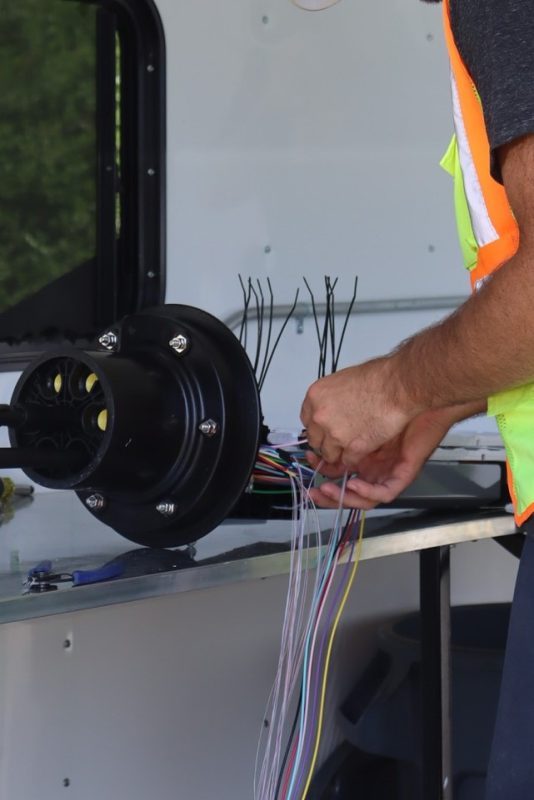

Our fiber optic splicing crew works to keep high-speed connections running strong in the field.

The Tools of the Trade: What You Need to Make It Happen

Let’s talk gear. Fiber optic splicing requires some pretty high-tech tools. These aren’t your average DIY shop supplies, these are specialized pieces of equipment that ensure precision and reliability.

- Fusion Splicer: This is the star of the show. It aligns the fiber strands and fuses them together using an electric arc.

- Cleave Tool: Imagine a glass cutter, but much more precise. It helps make sure the fiber ends are cleanly cut.

- Microscope: No, it is not for looking at bugs. This tool reveals microscopic imperfections you would never see with the naked eye on the inner core of a fiber that is thinner than a strand of hair.

- Splice Enclosures: Think of these as the protective cases that keep your hard work safe from dirt, moisture, and other elements.

- Testing Gear: This is where you find out if your work truly holds up. It pushes light through the fiber you just spliced to measure loss, continuity, and overall performance, making sure every connection meets the standard before it goes live.

Knowing your tools inside and out is essential. Just like any craft, it’s not just about the tools you use. It’s about how you maintain them, how you calibrate them, and how you keep them in top condition. After all, these fiber splicing tools are what stand between you and a flawless connection.

Training and Patience: The Path to Mastery

Becoming a fiber splicer isn’t an overnight gig. It’s a skill you hone over time, often starting as an apprentice or laborer. Whether you get your training through trade school, specialized courses, or on-the-job experience, it takes time.

And let’s talk about patience. If you’ve ever had to redo a project because the wind kept blowing dust onto your work, you’ll understand the importance of patience in this job. You could be working in harsh weather conditions, dealing with unexpected challenges, and trying to troubleshoot on the fly. But, with time, you learn to roll with it.

Why Fiber Splicing Is More Crucial Than Ever

So, why should we care? Here’s the thing: fiber optic splicing keeps the world connected. Every time you stream a video, make a call, or download an update, fiber optic splicing is what makes that smooth connection possible.

With new technologies like 5G, the rise of smart cities, and the demand for increased broadband access, the need for skilled fiber splicers is skyrocketing. This isn’t just a job; it’s a career that’s becoming more important with every passing year. And as governments invest billions into broadband infrastructure, it’s clear: fiber splicing is here to stay.

The Challenges You Don’t See

What you don’t see are the challenges fiber splicers face on the job. It’s not just about precision; it’s about the environment too.

- Weather: Dirt, moisture, and wind can all interfere with a perfect splice.

- Pressure: Deadlines loom, and the network needs to be up on time.

- Fatigue: Long hours require intense mental focus.

But fiber splicers push through these challenges because they understand how important their work is. It’s not easy, but the satisfaction of helping to build something that connects people? That makes it all worthwhile.

Why Fiber Splicing Could Be Your Next Career Move

Thinking about getting into fiber optic splicing? Let’s break it down:

- Pay: Fiber splicing offers competitive wages, especially as demand for skilled professionals continues to rise.

- Job Security: Fiber optics aren’t going anywhere, and neither are the job opportunities.

- Satisfaction: There’s a real sense of pride that comes with knowing your work keeps the digital world connected.

If you’re someone who loves hands-on work, enjoys solving problems, and wants to be part of something bigger, fiber optic splicing might just be the right fit. And the best part? It’s a job where you can see the tangible impact of your work.

Looking to the Future

So, where is fiber splicing headed? Fast. With initiatives to close the digital divide, expand broadband access, and deploy 5G, the demand for fiber is only going to grow. Cities and communities are moving toward smarter infrastructure, and fiber optic networks are at the core of it all.

And here’s the kicker: If you’re looking for a career that offers stability, purpose, and plenty of room for growth, now is the time to get on board.

The Quiet Craftsmen of the Digital World

The next time you’re streaming a video or sending a message without a glitch, take a moment to think about the fiber splicers out there making sure your connection stays strong. They’re the ones ensuring everything works as it should—no interruptions, no delays.

Fiber optic splicing may not sound glamorous, but it’s absolutely essential. These workers are the backbone of our digital lives. So, if you’re looking for a rewarding career that makes a difference, why not consider fiber splicing? It’s a field where precision, passion, and dedication truly shape the future.

Conclusion: Splicing the Future Together

Fiber optic splicing may seem like a small part of the puzzle, but it’s one that holds the entire network together. It’s the craft that keeps us connected, and it’s more essential than ever. So, whether you’re considering a career in telecommunications or simply appreciating the work that goes into every connection, remember this: fiber optic splicing is the behind-the-scenes champion of the digital age. And it’s a career that offers stability, satisfaction, and a chance to truly make an impact.