Why Fiber Optic Splicing Could Be Your Ticket to a Lucrative and Fulfilling Career

Fiber optic cables are the backbone of modern communication networks, carrying vast amounts of data over long distances at incredibly high speeds.

What is Fiber Optic Cable Splicing?

Fiber optic splicing is the process of joining two fiber optic cables together to create a continuous path for data transmission. In this article, we will discuss the different types of fiber optic splicing, the tools and equipment used for splicing, and the benefits and challenges of fiber optic splicing.

Two Types of Fiber Optic Splicing:

There are two types of fiber splicing: fusion splicing and mechanical splicing.

Fusion splicing is a process where two fiber optic cables are joined together by melting the ends of the fibers using an electric arc. This process creates a permanent connection between the two fibers. Fusion splicing is the preferred method for joining two fiber optic cables because it results in low loss connections that have a higher tensile strength than mechanical splices.

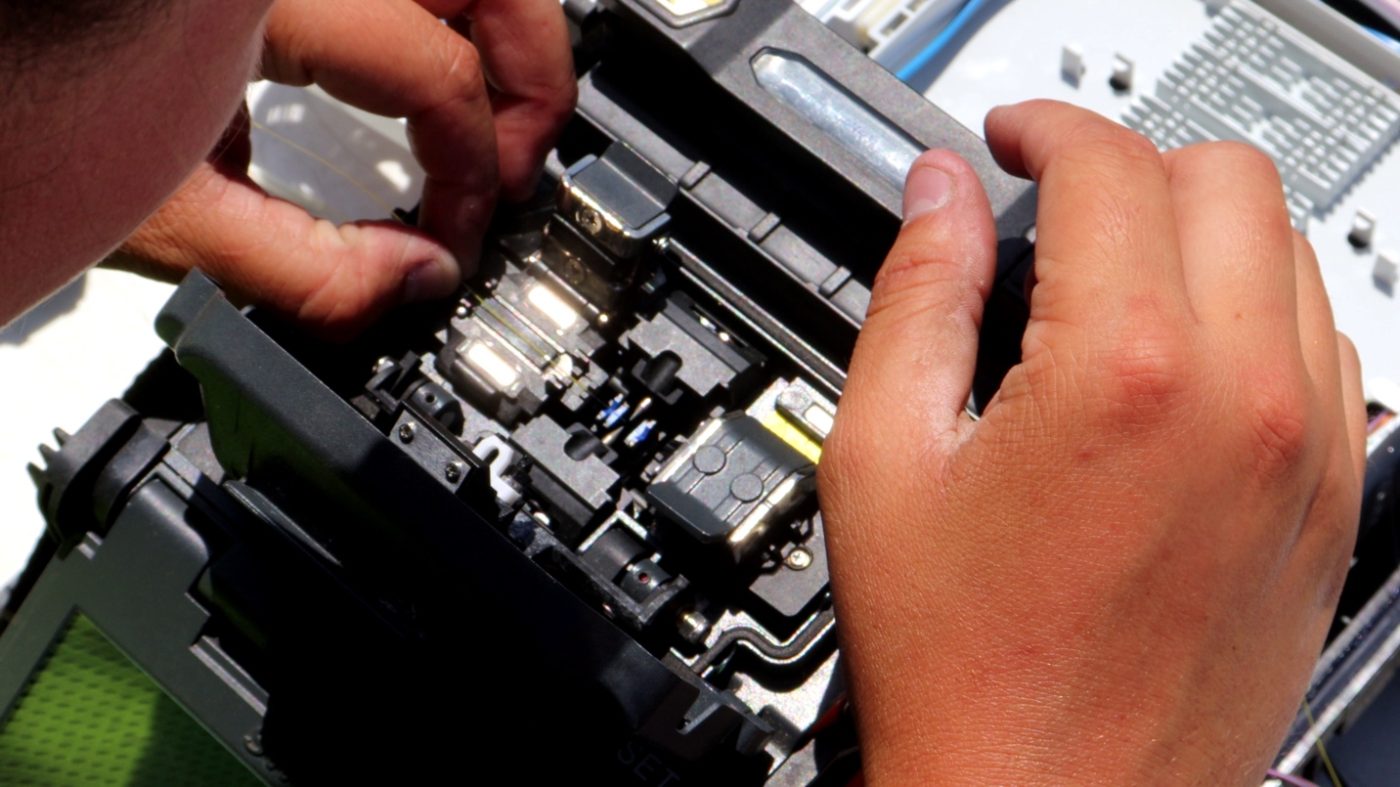

Fusion splicing requires specialized equipment, such as a fusion splicer, which aligns the two fibers and applies an electric arc to melt the ends of the fibers. The fibers are then fused together to create a continuous path for data transmission. Fusion splicing requires precision, and any misalignment or impurities in the fibers can result in a poor connection. It is therefore important to use high-quality fibers and to ensure that the splicing is done by a trained professional.

Mechanical splicing is a process where two fiber optic cables are joined together using a mechanical splice. A mechanical splice is a device that holds the two fibers in place and aligns them to create a continuous path for data transmission. Unlike fusion splicing, mechanical splicing does not require melting the fibers together, making it a simpler and less expensive process.

Mechanical splicing is less reliable than fusion splicing and can result in higher loss connections. However, it is still widely used for temporary connections or in situations where fusion splicing is not possible, such as when working with pre-terminated cables.

Tools and Equipment Used for Fiber Optic Splicing:

Fiber splicing requires specialized tools and equipment, including:

Fusion Splicer: A fusion splicer is a device used for fusion splicing. It aligns the two fibers and applies an electric arc to melt the ends of the fibers, creating a permanent connection.

Mechanical Splice: A mechanical splice is a device used for mechanical splicing. It holds the two fibers in place and aligns them to create a continuous path for data transmission.

Fiber Cleaver: A fiber cleaver is a tool used to cut the fiber optic cable cleanly and precisely, ensuring a clean and smooth surface for splicing.

Fiber Optic Stripper: A fiber optic stripper is a tool used to remove the protective coating from the fiber optic cable, exposing the bare fiber for splicing.

Alcohol and Wipes: Alcohol and wipes are used to clean the fibers before splicing, ensuring a clean and smooth surface for splicing.

Benefits and Challenges of Fiber Optic Splicing:

Fiber splicing offers several benefits over other methods of joining fiber optic cables, including:

Low Loss: Fusion splicing results in low loss connections, meaning that less of the signal is lost during transmission. This makes fusion splicing ideal for long-distance communication networks where high signal strength is essential.

High Tensile Strength: Fusion splicing creates a permanent connection between the two fibers, resulting in a higher tensile strength than mechanical splices. This makes fusion splicing ideal for applications where the fiber optic cable is subject to stress or tension.

Cost-effective: Mechanical splicing is a less expensive alternative to fusion splicing, making it a popular choice for temporary connections or situations where cost is a significant consideration.

Versatility: Fiber optic splicing is a versatile method of joining fiber optic cables that can be used in a variety of applications, including long-distance communication networks, local area networks, and data centers.

Despite its benefits, fiber optic splicing also presents several challenges, including:

Complexity: Fiber optic splicing is a complex process that requires specialized tools and equipment, as well as a high degree of skill and precision. As a result, it is typically performed by trained professionals with extensive experience in fiber optic splicing.

Fragility: Fiber optic cables are delicate and can be easily damaged, particularly during the splicing process. Any damage to the fibers can result in a poor connection, leading to signal loss or other issues.

Weather and Environmental Factors: Fiber optic cables are susceptible to damage from extreme weather conditions, such as high winds, heavy rain, or snow. In addition, exposure to sunlight or other environmental factors can cause the fibers to degrade over time, leading to reduced signal strength or other issues.

Conclusion and Industry Outlook:

Fiber optic splicing is an essential process for creating a continuous path for data transmission in modern communication networks. While both fusion splicing and mechanical splicing offer unique advantages, fusion splicing is the preferred method for permanent connections due to its low loss and high tensile strength.

Regardless of the method used, fiber optic splicing requires specialized tools and equipment, as well as a high degree of skill and precision. It is important to work with trained professionals who have extensive experience in fiber optic splicing to ensure a reliable and effective connection.

Fiber optic cable splicing can be a well-paying job, particularly for those with specialized training and experience. The salary for fiber optic cable splicers varies depending on factors such as location, experience, and type of employer. However, those with specialized skills and experience in the field may earn higher salaries.

It is worth noting that fiber optic cable splicing can be a physically demanding job that may require working in tight spaces or at heights. It may also involve working outdoors in various weather conditions. Nevertheless, for those with the necessary skills and experience, fiber optic cable splicing can be a rewarding and well-paying career.

The job market for fiber optic cable splicers is favorable, with steady demand for these professionals in various industries. The increasing demand for high-speed internet, data centers, and mobile networks has led to a growing need for fiber optic cable installation and maintenance services. In addition, the deployment of 5G networks is expected to create new job opportunities for fiber optic cable splicers.

Overall, the job market for fiber optic cable splicers is expected to remain stable, with steady demand for these professionals in various industries.

How to Get Involved:

Fiber optic splicing is one of the newest skills in the telecommunications industry, and National OnDemand hires Fiber Splicers at all skill levels. We employ new splicers as well as veteran, experienced splicers. National OnDemand sets fiber splicers up to succeed by bringing them along in a manner that is suitable to the skill set they bring to the job. Learning the ropes Fiber Optic Splicing is a step-by-step process that National fully understands.

Essential traits of a solid fiber splicer are a great attitude, punctuality, reliability, and a desire to learn. Prospects with these qualities are eligible for a spot on the team where they can grow and enjoy a meaningful career with National OnDemand. For new splicers, our training program is designed to teach precisely how the job should be done.

National ensures new splicers are ready to execute before sending them out into the field. By that time, they have learned the basics such as how to obtain the right tools and how to install brackets on utility poles.

New fiber splicers continue to move through the training process until they have learned the skills necessary for solo work. Our trainers observe and guide novice splicers such that they learn the proper method for executing each step. In a few short weeks, new splicers complete training and are ready to do the job on their own.

National OnDemand teaches new fiber optic splicers about different systems, equipment, and enclosures. Since we understand that fiber splicers may work with different machines, we cover the differences in our training program, as well as how to troubleshoot problems when a component is not functioning properly.

The fiber optic splicing position is important because as coaxial cable begins to fade in popularity, fiber optic cable will replace it as the standard for high speed internet customers.

You can quickly start your career with National OnDemand. We will train you and get you ready for your new career as a fiber optic splicer. See all our opening by visiting www.NationalOnDemand.com/careers. Contact us today to start your new journey now.

Anytime. Anywhere.

Q. What is fiber optic splicing?

Fiber optic splicing is the process of joining two fiber optic cables so that light signals can travel continuously without signal loss.

There are two main types:

– Fusion splicing — the ends of the fibers are melted together (via an electric arc), creating a permanent, low-loss connection.

– Mechanical splicing — the fibers are aligned and held together using mechanical fixtures. It’s less permanent and generally used when fusion splicing isn’t possible.

Q. What tools and equipment do I need?

To work as a fiber splicer, you’ll use specialized gear such as:

– Fusion splicer — aligns fibers and applies an arc to fuse them.

– Fiber cleaver — cuts the fiber cleanly and precisely.

– Fiber optic stripper — removes coating so the bare fiber can be worked on.

– Cleaning supplies (alcohol, wipes) — ensure fibers are clean before splicing.

Plus smaller accessories, test equipment, and sometimes enclosures, boots, etc.

Q. What are the advantages and challenges of this job?

Benefits

– Versatility — applicable in telecom, data centers, long-haul, etc.

– Growing demand — as fiber and 5G expand, more splicers are needed.

Challenges

– Delicate work — fiber is fragile and misalignment causes signal loss.

– Environmental conditions — working outdoors in wind, rain, heat, etc.

– Steep learning curve — precise skills, tools, and patience needed.

Q. Can someone new to the field become a fiber splicer?

Yes — many companies (including National OnDemand) hire beginners and train them on the job. Learn More about National OnDemand’s training philosophy

Key traits that help:

– Positive attitude, punctuality, reliability

– Willingness to learn

– Attention to detail and care in handling delicate materials

By the end of training, you’ll be able to splice on your own, having learned everything from tool setup to troubleshooting.

Q. Is fiber splicing a stable, well-paying career?

Yes — fiber splicing is seen as a steady and essential role in modern networks.

With the rise of fiber optics, data centers, and 5G, the need for splicing professionals continues to grow. Read more about the stability of fiber splicing

Compensation depends on experience, location, and employer, but splicers with specialized skills often command higher salaries.

Q. How do I get started?

– Explore related positions that can serve as a pathway to a splicing career. Roles such as fiber construction ground hand, aerial lineman, or last-mile fiber technician offer valuable field experience, exposure to fiber installation practices, and a solid understanding of how network builds come together. With time and training, many professionals successfully transition laterally from these positions into dedicated splicing roles.

– Apply even if you don’t yet have all skills — many employers train people from the ground up.

– Show that you have good attitude, reliability, and willingness to learn (often more important than prior experience).